So this file is 7" inches at the widest, Automatic Nesting put 0,0 for the next part at 7. Tap, and "G90" it into the original G-Code. If I had to do a different orientation to get an extra part in a rem, I would do a separate "part", create. The easiest way for many of the same part in the same orientation was a G90 code. I did it this way, and it really helped me learn G-Code. Cut and Paste Exterior G-Codes in between interior parts. The problem was all the interior cuts cut first, and then the exterior cuts. If I recall correctly, manufacturing standard practice is 0. If I did one part and ran it through the nesting program, it would lose one part per sheet because it wouldn't put a small enough gap in between parts due to shape. For multiples of parts that are squarish right click and array. SheetCam had tools to move parts around on the bottom of the screen for flipping, rotating, and incremental movements. Become a Contributing Member to gain access to this feature.

#Sheetcam nestinq download

You do not have access to view or download this file.

I had these parts and tried always to fit 4 out of a sheet, didn't think it was possible until running it in mynest. For the few jobs that I have that require nesting, I just draw the sheet in CADinsert my parts and manually nest them, save as dxf and import to SheetCAM for processing. Re: Nesting None worked that great and are finicky. I'm just thinking ahead, and mostly curious. Not really at a point where this is critical information, and at my level the cost savings in material due to efficient nesting wouldn't justify the expense of a commercial nesting program. LOL I'm just curious Or, do you create the individual parts, and then run through a nesting program? If so, what program do you use I assume you're happy with it, if you're using it. Now that I have an interest, I know I've seen other guys mention it in their posts. For general topics and questions that do not fit into any of the other categories or forums.

#Sheetcam nestinq free

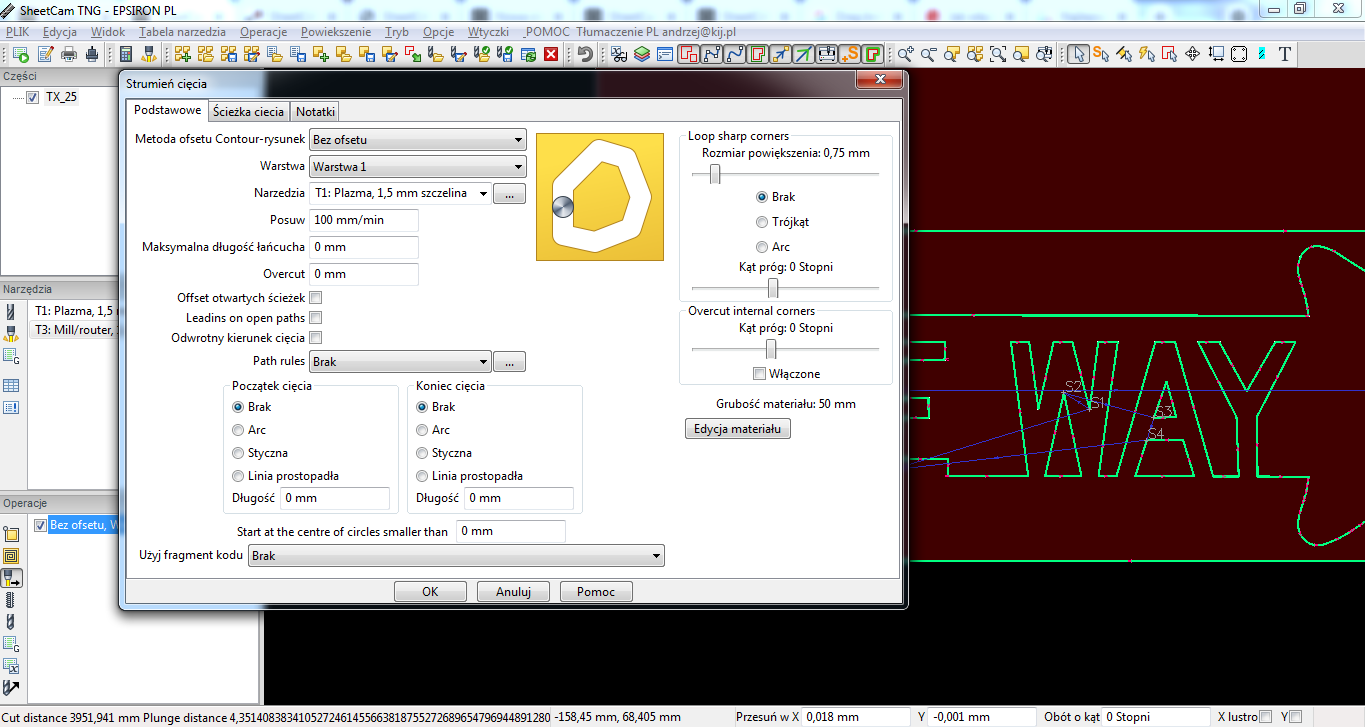

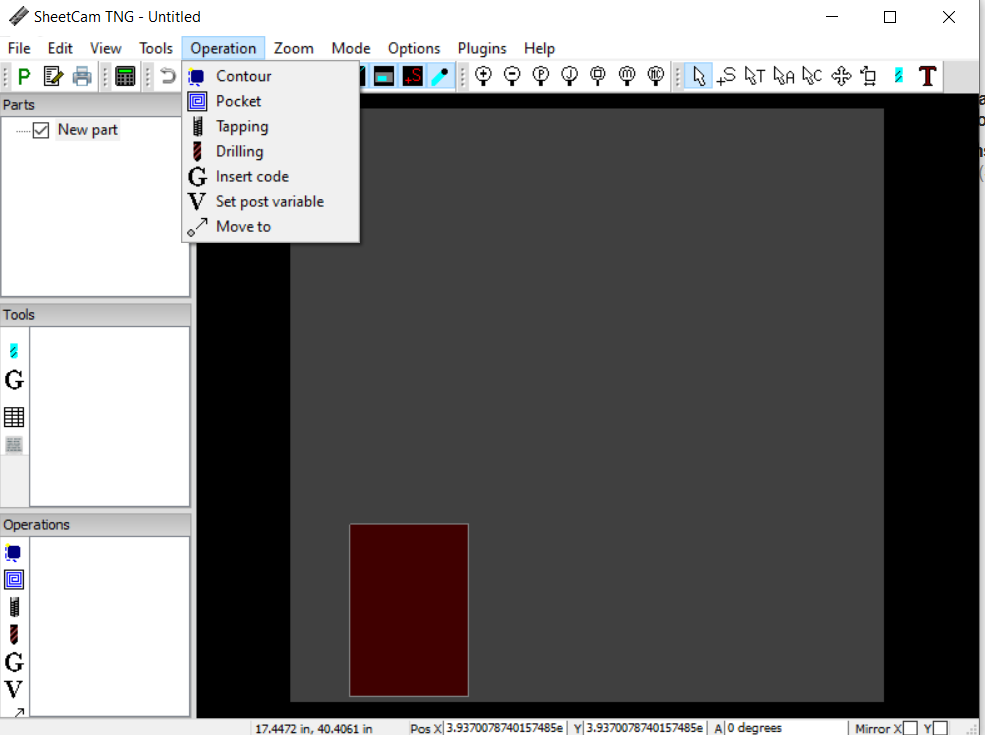

Since a lot of this real basic stuff is fresh in my mind, feel free to reach out to me if you need help, I can share some of the baby steps with you. I'm still in basic mode but I've cut a few really nice things already. Definately a learning curve for someone that never took CAD classes., Frustrating at times, but possible. If they aren't right I go back to tha CAD drawing and work on it and then try it again. After you've cut a few things with your machine, you'll know what Sheetcam files are supposed to look like. What I found most helpful is to import a drawing(dxf) into Sheetcam and run "simulation" on the computer screen, to see if it runs properly. I've found hundreds of free dxf files online, many of them need a little modifying which is a good way to leard CAD, and I also just purchased a boatload of files from Sign Torch. I been using mine about a month now, and with help from this site, I'm getting better at creating, or at least modifying my own DXF files. I use Turbo Cad, it came with my machine, but I hear it's relatively cheap. That's all you need, other than a Cad Program to modify and create drawings.

0 kommentar(er)

0 kommentar(er)